Description

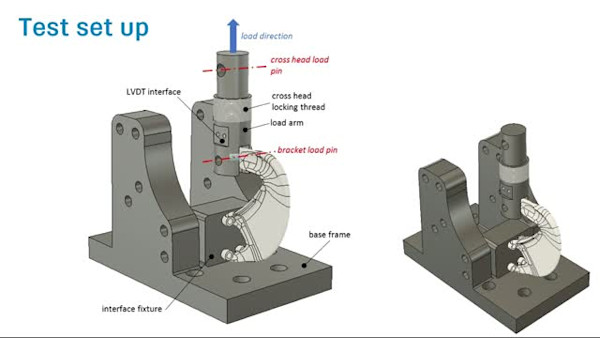

Autodesk has historically developed software and provided consulting services for metal additively manufactured (AM) lattice-type structures. Common powder-bed processes include SLM (Selective Laser Melting) / DMLS (Direct Metal Laser Sintering), and EBM (Electron Beam Melting). When considering real-life applications of these structures, many assumptions are made about the characteristics of the manufactured material. Among others, these include strength, elastic moduli, thermal properties, material density, surface finish, and structural stability. These characteristics are affected by many factors, including machine parameters, build orientation, and feature size. This session features Autodesk Explicit Solver, Nastran, Netfabb, Within.

Key Learnings

- Understand the challenges of mechanical characterization of metal additively manufactured structures

- Explore the impact that feature size has on mechanical properties

- Learn about elastic properties and failure modes of AM parts and lattice structures

- Investigate the application of current simulation tools when applied to lattices

Downloads

Tags

Product | |

Industries | |

Topics |

People who like this class also liked

Industry Talk

Maximizing the Benefits of Generative Design

Instructional Demo